PRODUCT

Product

We are dedicated to make world-class

products and working for customer satisfaction.

Nitrogen Generation System

Products

- Membrane Type

- PSA Type

Membrane Type

Gas separation with membrane uses the principle of selective gas permeation for

the membrane.

Membrane type-nitrogen generator uses a hollow-fiber type gas separation

membrane that has the property of permeating oxygen more easily than nitrogen.

In other words, when compressed air flows into the polyimide hollow-fiber

membrane, nitrogen, which is relatively slowly permeated through the high

pressure side (inside the hollow-fiber), passing through the wall (membrane) of

the hollow-fiber, and oxygen is passing through the low pressure side (outside

the hollow fiber) then permeated and released into the atmosphere.

CONTACT US

Inquiries about purchasing original equipment

- Sales Team of Dongwha Pneutec

- A/S Team of Dongwha Pneutec

- sales@dhkomp.co.kr

- service@dhkomp.co.kr

Quotation and other inquiries

- TEL

- FAX

- 051-974-4800

- 051-974-4896

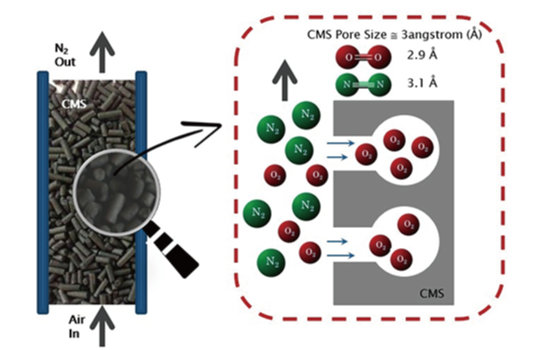

PSA(Pressure Swing Adsortion) Type

Pressure Swing Adsorption (PSA) technology refers to a technology that separates

a gas from the air using the difference in the adsorption power of the crystal

gas of Molecular Sieve.

In other words, adsorption is defined as binding gas molecules to an absorbent

which is a solid material through molecule absorption.

The PSA device separates gas mixtures using the difference of the adsorption

power for gases exerted by various adsorbents in the form of individual or

compound types.

Compressed air passes through the Molecular Sieve layer of crystal structure

with micro perforation in the gas separation process, and the gas is to be

adsorbed by the adsorbent, and separated passes freely through this layer.

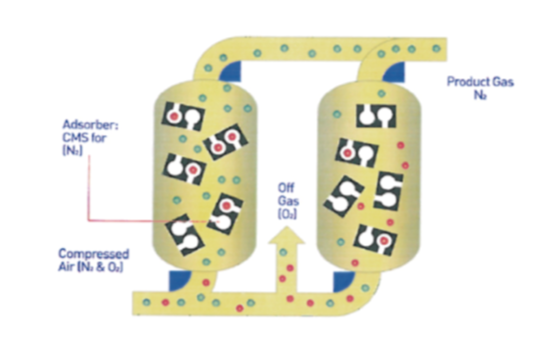

PSA nitrogen generator applies dehumidified compressed air into two or more

adsorption towers that are filled with an adsorbent called CMS (Carbon Molecular

Sieve) and repeatedly performs the pressurization-> adsorption-> decompression->

purge steps to continuously generate high-purity nitrogen.

CONTACT US

- Sales Team of Dongwha Pneutec

- A/S Team of Dongwha Pneutec

- sales@dhkomp.co.kr

- service@dhkomp.co.kr

Quotation and other inquiries

- TEL

- FAX

- 051-974-4800

- 051-974-4896